- 10 Cable Street, Avon Industrial Area Dundee KwaZulu Natal South Africa 3000

- registration@coinitcenter.com

- +2787

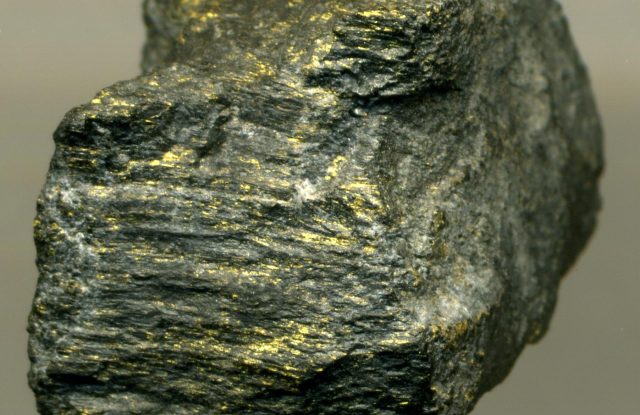

The process begins when the refinery facility receives the raw material to extract gold. This can include ore, rocks, gold nuggets, scrap gold, jewellery, and doré bars.

This process of extensive smelting involving extreme heat, pressure, and several chemicals results in the removal of various impurities from the gold.

This refers to the process of verifying the purity or weight of a gold piece. Gilded requires all its gold to contain a minimum yield of 99.99 percent pure gold.

After the assaying process is complete, the gold is ready to be reformed into many different types of moulds. It can be formed into a gold bar or coin.

The process begins when the refinery facility receives the raw material to extract gold. This can include ore, rocks, gold nuggets, scrap gold, jewellery, and doré bars. Doré bars have a gold purity of 80% and are directly produced by miners. The refinery takes that raw material and reliquefies the metal in an extremely hot furnace, as gold’s melting point is a scolding 1,065 degrees Celsius. Here, various chemicals are added to the molten mix to isolate the gold from the other, less desired metals. This process of extensive smelting involving extreme heat, pressure, and several chemicals results in the removal of various impurities from the gold.

After the purification process is complete, a sample from that round of smelting is used in an assay to determine the precise purity of the gold content. Assaying refers to the process of verifying the purity and/or weight of a gold piece. Gilded requires all its gold to contain a minimum yield of 99.99 percent pure gold, otherwise known as 24-karat gold.

After the assaying process is complete, the gold is ready to be reformed into many different types of moulds. It can be formed into a gold bar or coin, or it can be developed for use in electronics, furniture, buildings, and more.

Gold refining takes an object consisting of any percentage of gold to make a final product that consists of only pure gold. Once the pure gold content is thoroughly separated from the other metals within the alloy, it can be used to serve myriad purposes. It is a necessary process leveraged by gold dealers, retailers, resellers, and pawnbrokers to accept objects consisting of gold. Only through gold refining can the actual gold content be measured and appraised to be recycled into a new gold piece. The purer a gold bar is, the more value it holds. The process of refining allows for a higher quality bar to be created for investors to access.

It is a necessary process leveraged by gold dealers, retailers, resellers, and pawnbrokers to accept objects consisting of gold.

Only through gold refining can the actual gold content be measured and appraised to be recycled into a new gold piece.

The purer a gold bar is, the more value it holds. The process of refining allows for a higher quality bar to be created for investors to access.